What is WMS in Logistics: Key Features, Benefits, and Real Use Cases

Ditstek Blogs

A Warehouse Management System is the backbone of smooth warehouse operations. When people ask what is WMS in logistics, they’re referring to a software system that handles the complete flow of daily warehouse activities. It serves as the core platform that supports every other tool a warehouse may adopt.

A WMS covers a wide range of functions, from receiving goods and managing storage locations to guiding teams through picking, packing, shipping, and maintaining accurate inventory levels throughout the process.

This blog shares the role of warehouse management systems, key features, benefits, and use cases in logistics and supply chain.

Build a WMS That Fits Your Daily Operations!

Skip the one-size-fits-all tools. Get a system that mirrors how your team actually works and scales as your business grows.

What Is Warehouse Management?

Warehouse management refers to the systems and practices used to control and streamline operations within a warehouse daily. It covers tasks like receiving goods, arranging storage space, planning labor, tracking inventory, and completing orders accurately and on time.

Effective warehouse management is really about bringing all these activities together in a coordinated way, so the entire operation runs efficiently, boosts productivity, and keeps overall costs to a minimum.

How WMS Works Inside Logistics Operations

It starts the moment new stock arrives. Teams scan items, the system records them instantly, and it tells workers where to place everything. Once things are stored, the system continues to monitor. Every time something moves, the count updates in real time.

When orders land, WMS decides the best path for picking items. Instead of walking in circles, workers take shorter routes and finish faster. On top of that, packing becomes convenient as every item is already verified before it reaches the table.

The next step is shipping; labels are printed, orders match, and the system sends updates to the right places. Customers get clearer timelines, and your team gets fewer calls asking where the shipment is. Behind all of this is something even more valuable. The warehouse runs the same way whether it’s a slow Tuesday or a hectic holiday week. That steady rhythm is what keeps operations from spinning out during busy periods.

To make this flow even stronger, many companies pair their WMS with powerful tools like Business workflow automation, which reduces repeated steps, avoids missed tasks, and puts tasks on automation. It also improves the speed of tasks and ensures they are completed on time.

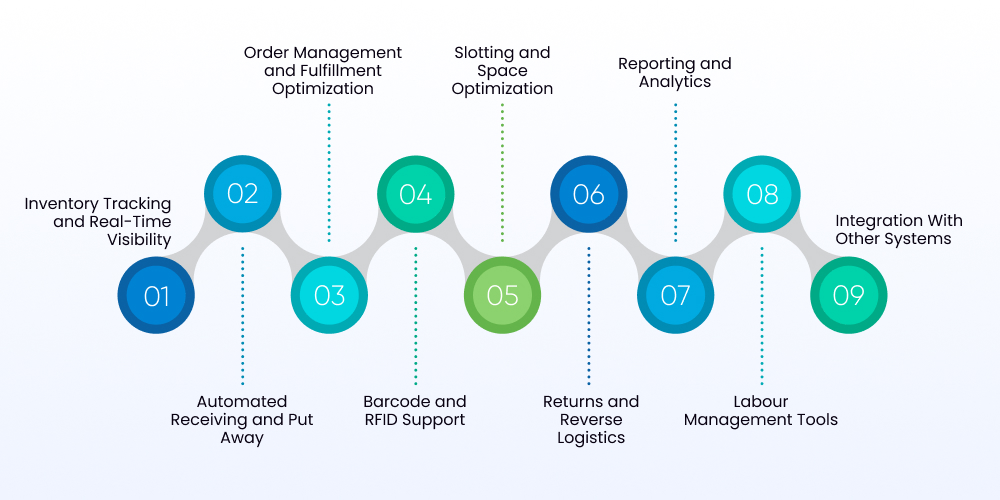

Key Features of WMS For Logistics

A good warehouse management system doesn’t try to overwhelm teams with complicated dashboards. It simply provides the tools to run daily work without slowing the teams down. Here’s how the core features usually help in real situations.

Inventory Tracking and Real-Time Visibility

A warehouse management systems lets teams know what’s in stock, what’s running low, and what moved five minutes ago. It’s a great relief for any manager who has dealt with unexpected shortages right in the middle of a busy day.

Automated Receiving and Put Away

When new items arrive, the system guides workers on where to place them. This stops things from being dropped wherever there’s space. Over time, this alone saves hours that usually get lost in hunting for misplaced items.

Order Management and Fulfillment Optimization

Orders flow in from different places. The system sorts them and, when possible, groups them, helping your team finish them faster. It keeps everyone on track even when order volume spikes without warning.

Barcode and RFID Support

Simple scans replace manual entries, which reduces the chances of mistakes and offers fast updates. Most warehouses notice the improvement within the first week of using a WMS.

Slotting and Space Optimization

Over time, the system learns which items move faster and suggests better spots for them. A small change like this can free up noticeable space and make everyday picking smoother.

Returns and Reverse Logistics

Returns can easily pile up if not handled correctly. A WMS organizes them so that damaged, restockable, or replacement items don’t mix. This keeps your shelves clean and your team focused.

Reporting and Analytics

You get clear numbers on what’s slowing down your floor, which products move fastest, and where staff spend the most time. Insights like these help you fix small inefficiencies before they grow.

Labour Management Tools

Instead of guessing how many people you need on a shift, the system gives you data to plan better. It reduces overtime surprises and keeps workloads reasonable.

Integration With Other Systems

Whether you use ecommerce tools, accounting software, or transport systems, a strong WMS connects with them. This avoids double-entry and removes another headache from your day.

Most modern WMS platforms connect with ERPs, accounting tools, and other business apps. Some companies even pair them with communication tools powered by AI chatbot development to handle order queries faster.

See How a WMS Works for Your Industry!

From e-commerce to cold storage, get a tailored walkthrough showing exactly how a WMS improves your workflows.

Benefits Of Using WMS In Logistics Business

The real strength of a warehouse management system shows up not on day one, but over weeks when daily problems start disappearing. Small improvements add up, and suddenly the whole warehouse feels lighter to manage.

Higher Order Accuracy and Faster Fulfillment

Mistakes drop because workers follow guided steps instead of relying on memory. Orders move out faster, and customers notice the consistency. It’s a quiet win that builds trust over time.

Reduced Labour Costs

When people stop searching for misplaced items or redoing wrong picks, the day runs smoother. Teams become more productive without feeling rushed, and overtime becomes easier to control.

Real Time Inventory Control

Up-to-date counts mean fewer surprises. Managers make decisions based on what’s actually available, not on what someone thought was available. That clarity alone prevents stock outs that can lead to lost sales.

Lower Errors and Fewer Returns

A small mis pick can cost more than the item itself once shipping and processing time add up. By catching mistakes early, the system saves money and avoids the frustration that returns usually bring.

Better Use Of Space

A WMS highlights which shelves sit underused and which areas feel cramped. A few rearrangements guided by the system can create room you didn’t know you had.

Improved Customer Experience

Fast and correct orders make customers feel confident in your business. Late or incorrect shipments do the opposite. Reliable fulfillment becomes a strong advantage in a competitive market.

Scalability During Peak Seasons

Busy months can shake even stable warehouses. A WMS keeps processes steady, even when order volumes jump suddenly. Instead of falling behind, teams stay in control.

Stronger Visibility For Decision-Making

With clearer data, planning becomes more factual and accurate. Managers start spotting patterns that help reduce future bottlenecks. These benefits don’t appear overnight, but once they do, it becomes hard to imagine running operations without this level of structure and clarity.

Real Use Cases of WMS in Canadian Logistics

A warehouse management system becomes more valuable when seen in real operational environments. Across Canada, many businesses began with small teams and growing bottlenecks, eventually finding stability through better visibility, connected systems, and automation. Below are real scenarios showing how a WMS—combined with IoT software and AI software development—strengthens different logistics operations.

E-commerce and Retail Distribution Centres

Online orders can surge without warning—quiet in the morning and overwhelming by afternoon. A WMS keeps operations stable by guiding optimal pick paths, updating stock in real time, and reducing shipment errors. Paired with AI software development, retailers can forecast order spikes, ensure faster fulfillment, and maintain accuracy at scale.

3PL Warehouses Serving Multiple Clients

Third-party logistics providers handle diverse SKUs across several clients, making accuracy essential. A WMS ensures each client’s inventory remains clearly separated and easy to track. With AI software development enabling automated reporting and predictive replenishment, 3PLs reduce operational friction and improve client satisfaction with precise, real-time data.

Manufacturing Warehouses

Manufacturers rely on timely availability of raw materials to avoid production delays. A WMS tracks materials, finished goods, and overlooked components with high accuracy. Integrated IoT sensors help monitor stock movement, while AI-powered analytics predict shortages in advance, keeping production lines running without costly interruptions.

Cold Storage and Food Logistics

Food logistics involve strict temperature zones, expiry timelines, and compliance rules. A WMS helps teams place products correctly and monitor expiry dates. IoT software plays a key role here—temperature sensors send live alerts, while AI systems forecast spoilage risk and optimize stock rotation, preventing waste and improving safety compliance.

Transportation and Logistics Providers

Many transportation companies focus on rapid movement rather than long storage. They cross-dock shipments and load trucks constantly throughout the day. A WMS supports this speed by organizing inbound and outbound flow, ensuring trucks leave on time. Combined with IoT-enabled tracking and AI route optimization, warehouses maintain clarity even in high-velocity environments.

These use cases makes it clear: whether the warehouse handles clothes, chemicals, groceries, or mixed freight, the system adapts and makes the workday smoother.

Cost of Implementing WMS In Canada

The cost of setting up a warehouse management system in Canada varies, but most businesses fall into a predictable range. Smaller warehouses usually spend around 15,000 to 40,000 CAD for software, setup, and basic training.

Mid-sized operations often land between 50,000 and 120,000 CAD, especially when they need custom workflows or extra modules.

Larger sites with deeper integrations, barcode tools, or complex layouts may go beyond 150,000 CAD.

The real surprise for many owners is how quickly the system pays for itself through fewer errors, better space use, and smoother daily work.

Get a Clear WMS Cost Estimate for Your Warehouse!

Understand what a custom WMS will cost based on your size, workflows, and integration needs without guesswork or hidden fees.

Why Canadian Businesses Prefer DITS for Custom WMS Solutions

Many companies reach a stage where off-the-shelf tools stop fitting their daily work. That’s when custom systems start making more sense, and this is exactly where DITS steps in with real value.

Fits Unique Workflows

Every warehouse runs differently. DITS builds custom flows that match how your team already works, instead of forcing you to adapt. This makes adoption smoother and helps operations speed up quickly.

Easy Integration With Existing Tools

Most businesses already use ERPs, scanners, or supply chain management software. DITS connects your WMS to these tools so everything talks to each other without extra manual steps. We also offer IoT app development services to integrate the WMS with your existing systems.

Scales As You Grow

When new locations open or product lines expand, our custom WMS solutions scale with your business without the need for system replacements.

Built For Long Term Efficiency

DITS designs systems that reduce repetitive tasks and improve coordination across teams. This is where their use of AI in development and quality assurance quietly boosts performance and keeps the system reliable for years.

Final Thoughts

A warehouse can look easy to manage from the outside. But inside, small delays and mix-ups can quietly drain time and money. That’s why many Canadian businesses eventually move toward smarter systems that keep everyday work predictable. A good WMS doesn’t try to change how you operate overnight. It simply brings order, clarity, and a steady rhythm to tasks that often feel scattered.

Companies that pair their WMS with the right tech partner see the biggest jump in results. At DITS, teams blend practical experience with tools like AI and even support areas such as IoT app development to fine-tune workflows. The goal is simple. Make warehouses easier to run, not harder.

FAQs

What Is WMS In Logistics and Why Do Businesses Use It?

A WMS helps you manage stock, guide picking, track orders, and keep warehouse tasks running smoothly. Companies use it to avoid errors, speed up work, and gain clearer visibility into daily operations.

Does A Small Warehouse Really Need a WMS?

Yes, especially when order volume grows and manual tracking starts slipping. Even small teams benefit from steady processes and fewer mistakes.

How Long Does It Take To Implement A WMS?

Most Canadian warehouses go live in a few weeks to a few months, depending on how much setup or data migration is needed.

Can A WMS Connect With Other Tools We Already Use?

Absolutely. Modern systems integrate with ERPs, scanners, accounting tools, and even business process automation services platforms to avoid double data entry.

How Does DITS Support Custom WMS Development?

DITS designs systems that match your processes instead of forcing one size fits all templates. Their team also uses AI during development and testing to keep the system stable and easy to scale.

What If Our Warehouse Needs Special Features?

DITS can customize modules for unique workflows, temperature zones, compliance steps, or fast moving inventory. You get exactly what fits your operation.

Can A WMS Work With Customer Service Tools?

Yes. Some businesses pair their WMS with tools like AI chatbot development to improve communication, track orders faster, or answer client questions in real time.

What Is The Average Cost Of A WMS In Canada?

Most businesses invest anywhere from 15,000 to 120,000 CAD. Costs vary based on warehouse size, features, and integration needs.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Get in touch