How Inventory Management Solutions Calgary Cut Costs and Improve Efficiency

Table Of Content

Published Date :

14 Jan 2026

For many Canadian businesses, inventory problems rarely warn business owners or managers before showing up. They show up quietly and can quickly turn a profitable supply chain into a loss. A warehouse that feels “too full,” a backorder that shouldn’t have happened, or cash that seems tighter than expected at the end of the quarter. None of these feels dramatic on its own, but together they can significantly harm business margins.

Rising labor costs, transportation delays, and unpredictable demand have made inventory accuracy a financial issue for Canadian companies. That is why inventory management solutions Calgary are helping business owners who want fewer surprises and better control. When inventory data is reliable, decisions around purchasing, staffing, and growth become easier to justify. When it’s not, every plan carries some level of risk.

This blog shares common inventory challenges and how effective inventory management solutions help businesses reduce costs and improve operational efficiency.

Build an Inventory System That Fits Your Business!

Talk to our experts about designing a custom inventory management solution aligned with your operations and growth plans.

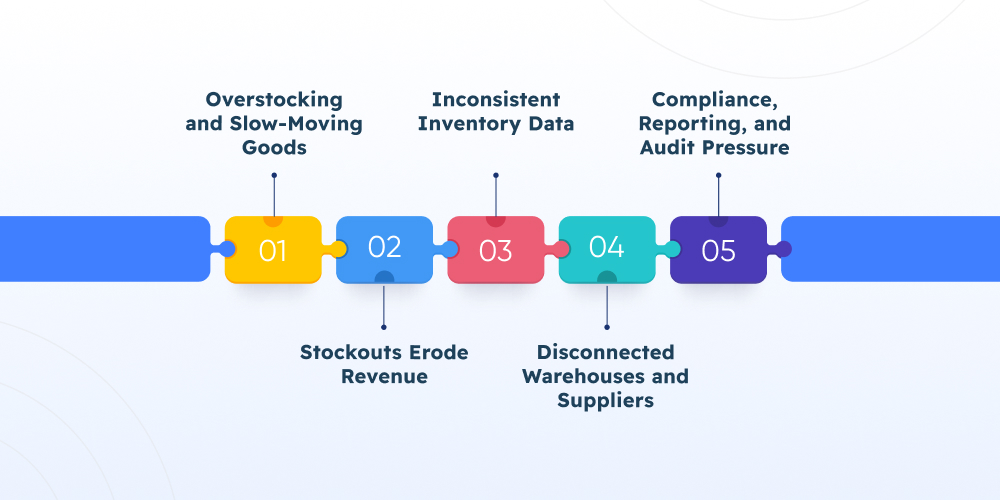

Common Inventory Management Challenges in Business

Inventory issues develop slowly as businesses grow, add locations, expand sales channels, or take on more complex supply relationships. Over time, systems that once worked well enough begin to show strain.

Overstocking and Slow-Moving Goods

Many Canadian companies discover that excess inventory quietly ties up working capital that could have been used elsewhere. Products sit longer than expected, storage costs rise, and financial flexibility shrinks, especially during periods of uneven demand.

Stockouts Erode Revenue

At the other end of the spectrum, missing inventory creates immediate disruption. A single unavailable item can delay entire orders, strain customer relationships, and force teams into reactive purchasing that often costs more and delivers less value.

Inconsistent Inventory Data

Spreadsheets, emails, and disconnected tools introduce version conflicts. Teams spend hours reconciling numbers instead of making decisions, and leadership loses confidence in reports that change from one meeting to the next.

Disconnected Warehouses and Suppliers

When inventory data does not update across locations in real time, availability becomes unreliable. This leads to rushed transfers, excess safety stock, and procurement decisions based on outdated information.

Compliance, Reporting, and Audit Pressure

For regulated industries, incomplete or inaccurate inventory records slow audits and increase exposure. Reporting cycles stretch longer, and teams feel the pressure to “fix the numbers” before reviews.

These challenges do not just affect operations. They influence cash flow, customer trust, and long-term planning.

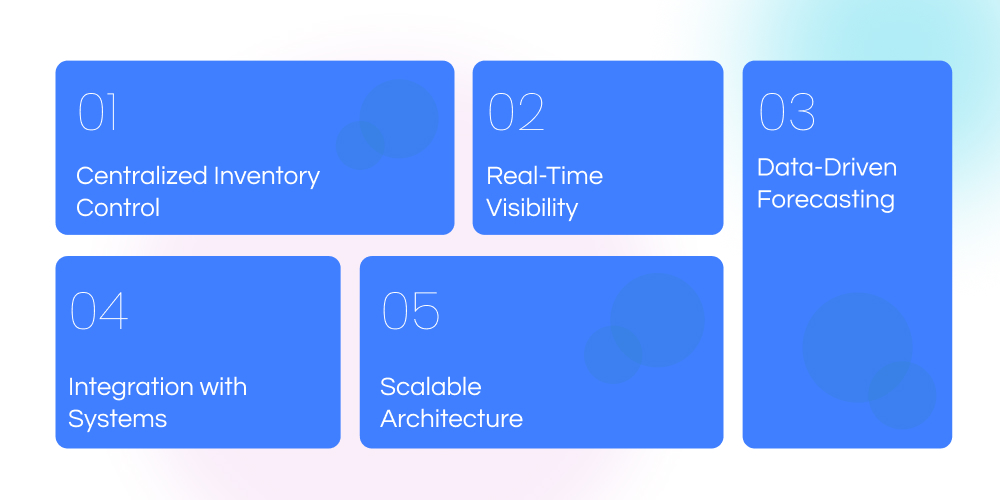

What Inventory Management Solutions Calgary Offers?

Modern inventory platforms are designed to eliminate uncertainty and provide clarity. They focus less on tracking items and more on supporting smarter business decisions.

Centralized Inventory Control

A single source of truth ensures that every department works from the same data. Whether inventory is moving between warehouses or sales channels, updates are immediate and consistent.

Real-Time Visibility

Live inventory updates remove delays caused by manual entry. Live inventory is tracked using IoT devices enabled with sensors and trackers. Teams can act quickly, confident that the data reflects what is actually on hand.

Data-Driven Forecasting

By analyzing demand trends and usage patterns, inventory management software helps businesses plan restocking based on evidence rather than assumptions. Teams use AI software or tools to analyze demand trends and usage patterns. This reduces the chances of excess stock and emergency purchases.

Integration with Systems

Inventory connects seamlessly with finance, procurement, and sales platforms, keeping operational activity aligned with financial reporting and revenue planning.

Scalable Architecture

As order volumes and locations increase, the system adapts immediately with the help of AI software without requiring major rework. Growth happens without introducing new inefficiencies. DITS provides AI software development services to companies in Canada and the United States who want to leverage the power of artificial intelligence to streamline operations across multiple locations.

At this point, inventory stops being a daily concern and starts functioning as a controlled, predictable business asset.

Request an Inventory Management Consultation!

Let’s review your current inventory challenges and identify where cost leakage and inefficiencies are hiding.

How Inventory Management Solutions Calgary Reduces Costs

Cost reduction comes from removing small inefficiencies that quietly drain resources every day. This is where inventory management solutions Calgary delivers measurable value for Canadian businesses that want tighter financial control without operational disruption.

Smarter Stock Levels

When inventory levels are aligned with actual demand, businesses avoid paying for excess storage, insurance, and handling. Overstocking becomes intentional rather than accidental, freeing up capital that would otherwise sit idle on warehouse shelves.

Reduced Wastage and Obsolete Inventory

Accurate tracking minimizes losses caused by expired, damaged, or misplaced goods. With better visibility, slow-moving items are identified early and addressed before they turn into write-offs.

Automated Processes and Reduced Overhead

Workflow automation replaces repetitive tasks like manual counts and reconciliations. Teams spend less time correcting errors and more time on work that adds value, which directly lowers operational labor costs.

Stronger Supplier Negotiations

Reliable demand insights offer leverage to procurement teams. Businesses can negotiate better pricing, avoid rushed purchases, and build supplier relationships based on predictable order patterns.

Improved Cash Flow and Capital

With clearer inventory movement and valuation, finance teams gain better control over cash flow. Forecasting becomes more accurate, and financial planning stops relying on estimates that change month to month.

Cost savings show up in balance sheets, audit reports, and calmer leadership meetings.

Improved Operational Efficiency Across the Organization

Cost control matters, but efficiency is where leadership teams feel the difference day to day. When inventory data flows cleanly across departments, operations stop reacting and start moving with intent.

Faster Order Fulfillment

Accurate inventory visibility removes delays between order placement and dispatch. Teams no longer pause to confirm availability or reroute orders at the last minute. Fulfillment becomes predictable, which directly improves customer experience and internal planning.

Streamlined Warehouse Operations

With warehouse inventory management software in place, picking, packing, and transfers follow structured workflows instead of improvised routines. Staff move with clarity, errors drop, and throughput increases without needing additional headcount.

Better Coordination Between Departments

Inventory data becomes a shared reference point rather than a point of debate. Sales commits confidently, procurement orders with precision, and finance reports on numbers it can defend. That alignment reduces internal friction and speeds up decisions.

Standardized Processes Across Teams

As businesses scale, inconsistency is often the hidden enemy. Standardized inventory workflows ensure that each location follows the same rules, reducing training time and operational variance.

Real-Time Dashboards

Leadership no longer waits for end-of-month reports. Live dashboards highlight risks early, whether it’s a supply delay or an unexpected demand spike. Problems are addressed before they become disruptions.

Efficiency, at this level, is not about working harder. It’s about removing obstacles so teams can work with confidence.

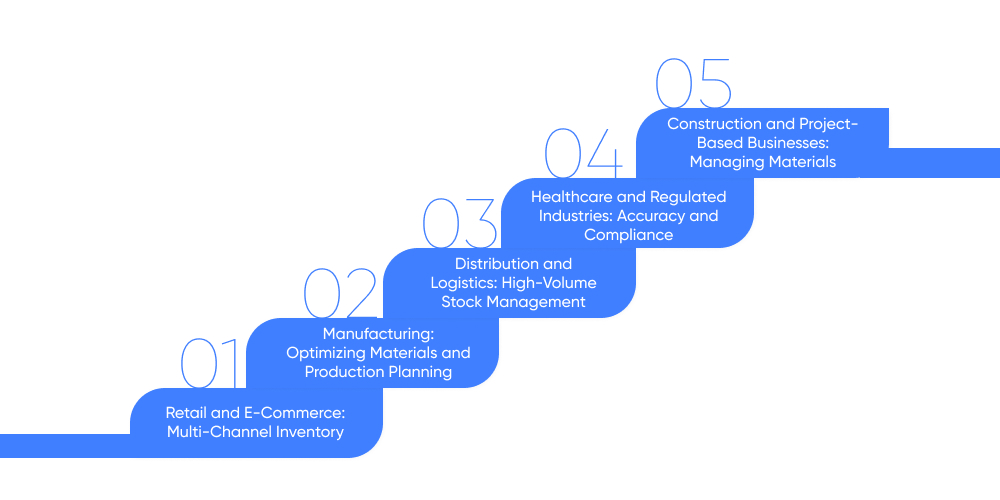

Industry Use Cases of Inventory Management Solutions Calgary

The value of modern inventory systems becomes clearest when viewed through real operational environments. Different industries face different pressures, yet the outcomes tend to converge around control, predictability, and cost discipline.

Retail and E-Commerce: Multi-Channel Inventory

Retailers often struggle to maintain consistent stock levels across physical stores, online platforms, and third-party marketplaces. Centralized inventory visibility helps avoid overselling, reduces excess safety stock, and ensures that promotions do not create fulfillment chaos. This becomes especially important during seasonal peaks when demand shifts quickly.

Manufacturing: Optimizing Materials and Production Planning

Manufacturers depend on precise timing. Too much raw material increases carrying costs, while shortages stall production lines. Accurate forecasting and live inventory data help align procurement with production schedules, reducing downtime and improving throughput without inflating inventory buffers.

Distribution and Logistics: High-Volume Stock Management

For distributors, speed and accuracy define competitiveness. Real-time tracking supports faster picking and dispatch, while consistent data across warehouses prevents duplication and misrouting. Over time, this leads to smoother operations and lower fulfillment costs.

Healthcare and Regulated Industries: Accuracy and Compliance

In healthcare, inventory mistakes are not just costly; they carry risk. Detailed tracking, audit trails, and expiration monitoring support compliance while ensuring critical supplies are always available when needed.

Construction and Project-Based Businesses: Managing Materials

Construction firms often juggle materials across multiple sites. Inventory visibility reduces overordering, limits theft or loss, and ensures materials arrive when crews are ready, not weeks early or too late.

Across industries, the pattern is consistent. Better inventory data leads to calmer operations and stronger financial outcomes.

Modernize Your Inventory Operations With Confidence!

See how a tailored inventory platform can reduce costs, improve accuracy, and support smarter decisions.

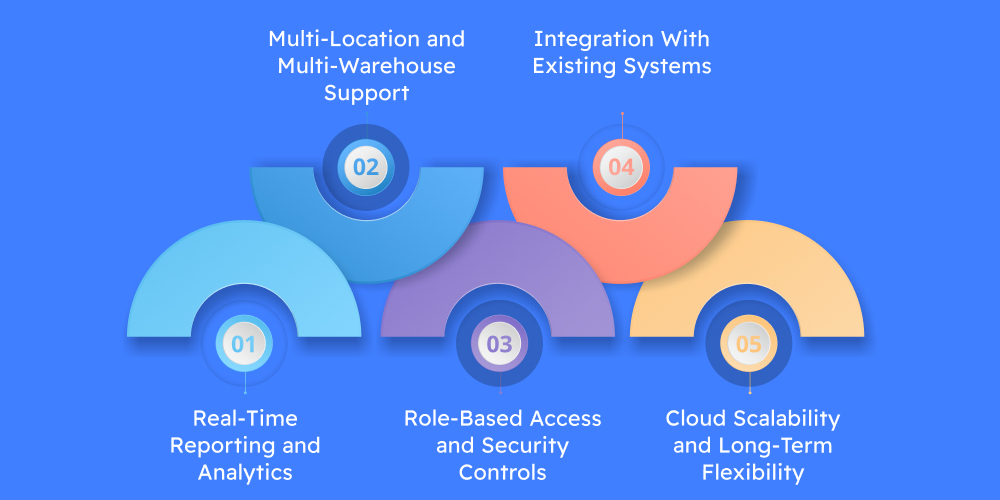

Key Features Companies Should Look For

Choosing the right inventory platform is not about feature volume. It is about selecting capabilities that support real operational decisions and long-term growth. Business leaders should focus on functions that reduce complexity rather than introduce it.

Real-Time Reporting and Analytics

Executives need more than static reports. Live dashboards that highlight stock movement, aging inventory, and demand trends enable leaders to act early rather than respond after losses occur.

Multi-Location and Multi-Warehouse Support

As businesses expand, inventory systems must handle multiple sites without creating data silos. A unified view across warehouses and branches ensures consistency and prevents duplication.

Role-Based Access and Security Controls

Not every user needs the same level of access. Clear permission structures protect sensitive data while allowing teams to work efficiently within defined boundaries.

Integration With Existing Systems

Inventory should not operate in isolation. The ability to connect with finance, sales, procurement, and supply chain management software ensures data flows smoothly across the organization without manual intervention.

Cloud Scalability and Long-Term Flexibility

A system should grow with the business. Cloud-based platforms support expansion, seasonal spikes, and future upgrades without disruptive infrastructure changes. At this point, inventory systems stop being tactical tools and start functioning as strategic infrastructure.

Why Choose DITS For Inventory Management Software Solutions

Selecting the right technology partner matters as much as selecting the right enterprise software. Inventory systems sit at the core of operations, and small design decisions can impact long-term business consequences. This is where DITS brings a practical, execution-focused advantage.

At DITS, inventory platforms are not treated as standalone tools. They are designed as part of an operational ecosystem, aligned with procurement, sales, logistics, and finance. Every solution is built to fit existing workflows instead of forcing teams to adapt to rigid systems.

At DITS, we use AI throughout software development, quality assurance, code maintenance, and customization. This approach improves reliability, reduces defects, and ensures that inventory platforms remain adaptable as business needs evolve.

DITS also supports advanced integrations, whether connecting inventory with Inventory management in supply chain processes or extending functionality through IoT development services where real-time asset or stock monitoring is required. The result is software that tracks inventory and supports informed, confident decision-making across the business.

Conclusion

Inventory does not have to be a constant source of stress or uncertainty. When systems are clear and data is reliable, day-to-day decisions become easier to make and easier to stand behind. Teams spend less time correcting mistakes and more time moving the business forward.

For Canadian companies, the real value of modern inventory management lies in control. Control over costs. Control over stock levels and how capital is used. With the right approach, inventory stops being a silent drain on resources and starts supporting growth in a practical, measurable way. That shift may feel subtle at first, but over time, it makes a noticeable difference in both operations and financial outcomes.

FAQs

How Do Inventory Management Systems Reduce Operational Costs for Businesses?

Inventory systems reduce costs by improving accuracy across purchasing, storage, and fulfillment. When stock levels reflect real demand, businesses avoid excess carrying costs, emergency procurement, and manual corrections. Over time, this leads to better cash flow control and fewer financial surprises during audits or reviews.

Are Inventory Management Solutions Calgary Suitable For Mid-Sized Businesses?

Yes. Mid-sized companies often benefit the most because they sit at a scale where spreadsheets no longer work, yet operational complexity is increasing. Modern platforms are modular, allowing businesses to start with core capabilities and expand as operations grow, without heavy upfront disruption.

How Long Does It Typically Take To Implement An Inventory Management System?

Implementation timelines vary based on complexity, integrations, and data readiness. For most Canadian businesses, a well-planned rollout takes a few weeks to a few months. The key factor is preparation, especially data cleanup and alignment with existing processes.

Can Inventory Systems Integrate With Existing Business Applications?

Modern inventory platforms are designed for integration. They connect smoothly with accounting tools, ERP platforms, supply chain management software, and even customer-facing systems. Some businesses also extend functionality with custom AI chatbot development to support internal queries or operational alerts without adding manual workload.

How Does DITS Approach Inventory Management Software Development for Businesses?

DITS takes a business-first approach to inventory management software development, focusing on how inventory impacts cash flow, operations, and decision-making. Solutions are designed around real workflows, not generic templates. This includes aligning inventory data with procurement, sales, and finance systems, ensuring the platform supports daily operations while remaining flexible enough to scale.

What Makes DITS Inventory Management Software Different From Off-The-Shelf Solutions?

Unlike off-the-shelf products, DITS builds inventory platforms tailored to specific business environments. Each solution is customized for industry requirements, integration needs, and operational complexity. DITS also integrates intelligence into development, using AI across coding, quality assurance, and customization to maintain performance, reliability, and long-term adaptability.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Digital transformation in healthcare streamlines operations, reduces administrative waste, strengthens revenue cycles, and enables data-driven decisions that support sustainable cost control and improved care delivery.

Reduce operational risks and errors by replacing manual, spreadsheet-based processes with dispatch management software.

Discover how bespoke MVP development services help Canadian companies reduce product risk, validate ideas faster, and build scalable products with confidence.