Ultimate Guide to Inventory Management Software for Small Manufacturing Businesses

Ditstek Blogs

For small manufacturing businesses, inventory problems rarely show up as minor issues. They surface as missed delivery dates, production slowdowns, and uncomfortable client conversations. A single stock mismatch can quietly disrupt an entire operation. As order volumes grow and product lines expand, manual tracking methods struggle to keep pace, leaving decision-makers often reacting.

This is where inventory management software for small manufacturing business operations becomes essential. It brings structure to inventory data, clarity to production planning, and control to costs. More importantly, it gives leadership teams reliable visibility into what is available, what is moving, and what needs attention before problems escalate.

Inventory Management Software For Small Manufacturing Businesses

In a manufacturing context, inventory management software is a centralized system that tracks materials, work-in-progress, and finished goods as they move through production. It connects inventory data directly to manufacturing activities as an operational control layer that leaders can rely on.

Manual tracking methods often look fine on the surface. Spreadsheets, paper logs, and disconnected tools work until volumes rise or product variations increase. Then errors creep in. Updates get delayed. Teams start working with outdated numbers. Production plans become challenging.

Software-driven inventory control changes that equation. Data updates in real time, stock levels reflect actual usage, and production teams operate from a single source of truth.

Ready to bring clarity to your inventory operations?

Talk to DITS about building an inventory management system tailored to your manufacturing workflows, designed for accuracy, scalability, and long-term growth.

Why Small Manufacturing Businesses Need Inventory Management Software

As manufacturing operations grow, inventory becomes an important business function. Cost overruns often begin quietly with excess raw materials, rushed purchases, or components sitting idle for months. Over time, these gaps eat into margins without drawing attention.

Production planning also suffers when inventory data is unreliable. Teams either wait for materials that were assumed to be available or rush jobs to compensate for shortages. Cash flow is also disrupted as capital gets locked into stock that does not move.

What changes with a structured inventory system is visibility. Leaders gain a clear view of raw materials, work-in-progress, and finished goods across the floor. And that shift alone often pays for the system faster than expected.

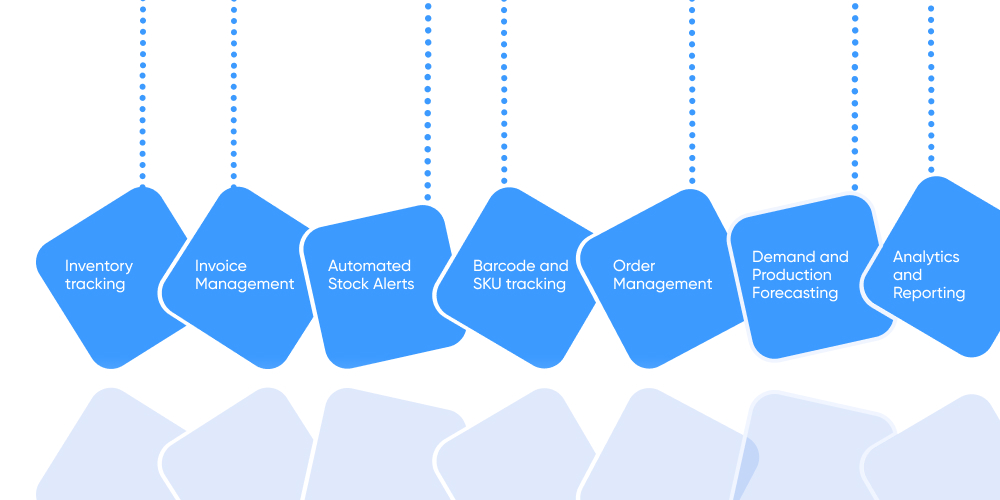

Core Features to Look For in Inventory Management Software

Not all inventory platforms are built with manufacturing realities in mind. For decision-makers, the focus should be on features that directly support production accuracy, cost control, and operational visibility.

Key capabilities that matter include:

Inventory tracking: Real-time inventory tracking that reflects actual material movement on the shop floor.

Invoice Management: Bill of Materials management to ensure every component required for production is accounted for before work begins.

Automated Stock Alerts: Automated stock alerts and reorder points that prevent last-minute procurement and production delays

Barcode and SKU tracking: Barcode and SKU tracking to reduce manual errors and speed up material handling

Order Management: Supplier and purchase order management to align procurement cycles with production schedules

Demand and Production Forecasting: Demand and production forecasting based on historical usage patterns

Analytics and Reporting: Reporting dashboards that translate inventory data into clear operational insights for leadership

The right combination of these features brings clarity. And once clarity becomes the norm, execution improves across teams.

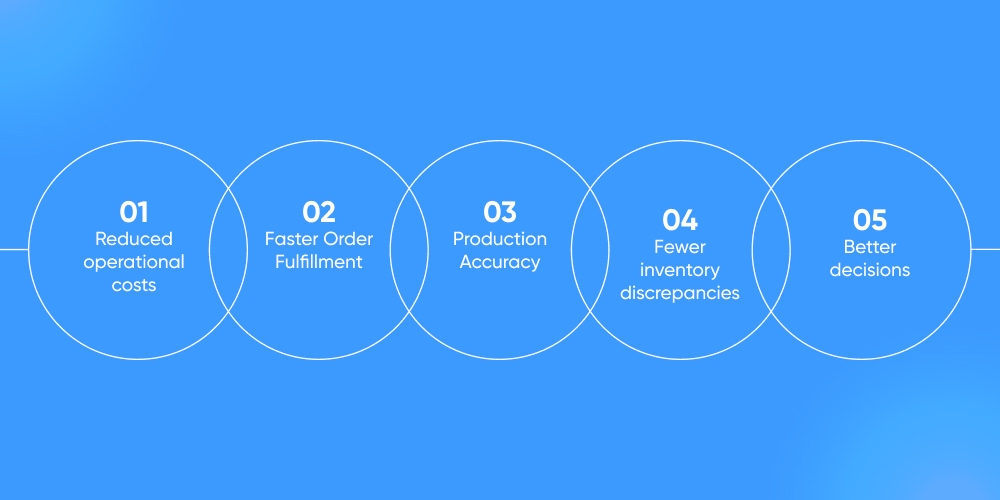

Key Benefits for Small Manufacturing Businesses

The impact of a well-implemented inventory system is felt quickly, often in places leadership did not expect. Operational efficiency improves, which improves decision-making confidence.

Some of the most noticeable benefits include:

Reduced Operational Costs

Reduced operational costs through tighter control over purchasing, storage, and material usage

Faster Order Fulfillment

Faster and more reliable order fulfillment because production teams work with accurate stock data

Production Accuracy

Improved production accuracy, limiting rework caused by missing or incorrect components

Fewer Inventory Discrepancies

Fewer inventory discrepancies between physical stock and recorded data

Better Decisions

Better, faster decisions supported by real-time visibility into inventory and production status

There is also a less obvious benefit. Teams spend less time firefighting and more time executing planned work. That shift changes how operations feel daily. Things run more smoothly, conversations become shorter, and performance discussions are based on facts rather than assumptions.

Struggling with stock mismatches, production delays, or rising inventory costs?

Let’s map your current inventory challenges and identify where automation and AI can deliver the fastest operational wins.

How Inventory Management Software Supports Manufacturing Growth

Growth in manufacturing is not linear. New clients, higher order volumes, and expanded product lines place pressure on systems that were never designed to scale.

An effective inventory platform allows production to scale without adding unnecessary complexity. Multi-location inventory tracking also becomes manageable, giving leadership visibility across warehouses, plants, or contract manufacturing sites.

Integration plays a key role here. When inventory connects with accounting, ERP, and production systems, data flows without friction. This is also where business workflow automation quietly delivers value by reducing manual handoffs and operational delays.

Common Implementation Challenges And How To Overcome Them

Even the right inventory system can struggle if implementation is rushed or poorly planned. Most challenges are predictable, which means they are also manageable with the right approach.

Data migration is often the first hurdle. Legacy systems and spreadsheets contain inconsistencies that surface only during transition. Cleaning and validating data upfront saves weeks of time spent on corrections.

User adoption is another common issue. Teams resist change when systems feel imposed. Practical training tied to daily workflows makes acceptance smoother.

Integration with existing tools can also slow progress, especially in environments linked to transport and logistics services. Clear integration planning and phased rollouts reduce disruption. Cost management is the final concern. Staggered implementation and prioritizing high-impact modules help control budgets without sacrificing outcomes.

When handled correctly, these challenges become checkpoints. And once passed, the operational payoff is tangible.

How To Choose Inventory Management Software For Small Manufacturing Business

Choosing the right platform is less about feature volume and more about operational fit. Cloud-based systems are often preferred by manufacturers because they reduce infrastructure overhead and support remote visibility. On-premise solutions still make sense in tightly controlled environments, but they require long-term IT commitment.

Another critical decision is custom versus off-the-shelf software. Prebuilt tools offer faster deployment, but customization becomes limited as processes evolve. Custom-built solutions align more closely with production workflows, compliance needs, and reporting expectations, especially when manufacturing operations are not standardized.

Total cost of ownership should be evaluated beyond licensing. Implementation, integrations, training, and future scalability all carry financial weight. The experience of development partner also matters. Providers with a manufacturing background understand production dependencies, not just inventory counts.

At DITS, this is where our approach stands apart. We use AI for software development, quality assurance, maintaining code quality, and deep customization. AI is embedded into every solution we build, helping manufacturers design systems that adapt as operations mature.

Role of AI And Automation in Inventory Management

Modern inventory systems are no longer limited to tracking quantities and locations. AI-driven automation is reshaping how manufacturers anticipate demand, manage risk, and respond to operational changes.

Predictive models analyze historical consumption, seasonal trends, and production cycles to forecast material requirements with greater accuracy. Automated alerts flag anomalies early, whether it’s unusual usage patterns or supplier delays. And over time, the system learns, improving its recommendations.

This is where AI and IoT in inventory management becomes particularly relevant. Connected devices feed real-time data into systems, enabling control over stock movement and condition. The result is fewer surprises, and better planning confidence.

Why Choose DITS for Inventory Management Software for Manufacturing

Manufacturing operations demand precision, not generic solutions. This is where DITS brings practical value. Our focus is not just on building inventory systems, but on building software solutions that align with how manufacturing businesses actually operate on the shop floor and across supply chains.

DITS takes a consultative, process-first approach. Before development begins, we map production workflows, material dependencies, and decision bottlenecks that directly affect cost and output. The result is software that supports real production scenarios, not theoretical use cases. Systems are designed to scale with volume increases, product variations, and multi-location operations without adding complexity.

AI plays a central role in how we deliver value. At DITS, AI is embedded across software development, quality assurance, code consistency, and customization. This ensures faster iterations, higher reliability, and solutions that adapt as operational data grows.

Choosing DITS means partnering with a team that understands manufacturing pressure points and builds systems that support confident, data-driven decisions.

Conclusion

Inventory challenges rarely announce themselves early. They build quietly, showing up later as rising costs, delayed production, or strained customer relationships. For small manufacturing businesses, addressing these issues proactively makes a measurable difference to operational stability and long-term growth.

The right inventory system brings discipline to material planning and clarity to production decisions. It replaces fragmented data with a unified view that leadership teams can trust. Over time, this visibility supports smarter scaling, stronger supplier coordination, and fewer operational surprises.

For executives, inventory management software is a strategic investment that strengthens execution, protects margins, and creates space for informed decision-making as the business evolves.

FAQs

What Is Inventory Management Software, and Why Is It Important for Manufacturing?

Inventory management software helps manufacturers track raw materials, work-in-progress, and finished goods in real time. It ensures production teams work with accurate data, reduces material waste, and prevents costly delays caused by stock shortages or overstocking.

How Long Does It Take To Implement Inventory Management Software?

Implementation timelines vary based on business size, data complexity, and integrations. For most small manufacturing businesses, a structured rollout typically takes between 6 to 12 weeks, including data migration, testing, and team training.

How Does DITS For Inventory Management Software For Manufacturing Support Custom Business Needs?

DITS For Inventory Management Software For Manufacturing is built around your production workflows rather than forcing standard templates. The solution is customized to match material flows, reporting requirements, and growth plans, ensuring long-term alignment with manufacturing operations.

Can Inventory Management Software Integrate With Existing Systems?

Modern inventory platforms can integrate with accounting, ERP, and production systems. This ensures seamless data flow across departments and improves visibility for both operational and financial decision-making.

Why Choose DITS for Inventory Management Software for Manufacturing Over Off-the-Shelf Tools?

DITS for Inventory Management Software for Manufacturing focuses on flexibility, scalability, and manufacturing-specific use cases. By embedding AI into development, quality assurance, and customization, DITS delivers systems that adapt as production complexity and volume increase.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Get in touch